Mission

In an era defined by climate change, resource scarcity, and geopolitical uncertainty, we believe materials science and engineering must deliver new solutions – ones that offer both advanced engineering performance while becoming part of, and blending into, ecological systems. We see this pursuit not merely as a driver for innovation, but as a responsibility to future generations.

That is why we conduct comprehensive research into the behaviour of such materials. We aim to develop innovative solutions that address today’s challenges while laying the foundation for the next frontier: engineered living materials that can respond, adapt, and ultimately “think” – much like natural systems.

Our work aligns with the principles of circularity, resource efficiency, and ecological responsibility, while also addressing the needs of ageing societies and resilient infrastructures.

Through interdisciplinary research, hands-on education, and collaboration with industry and society, we empower a new generation of scientists and engineers to lead the transition to a regenerative, high-tech future. Together, we develop materials — and mindsets — for a better world.

Research

Research description

At the Institute of Materials Science and Engineering at TU Clausthal, we conduct comprehensive research into the behaviour of materials and substances. Our aim is to develop innovative materials and processes that align with the principles of circularity, resource efficiency, and ecological responsibility, while also supporting ageing societies.

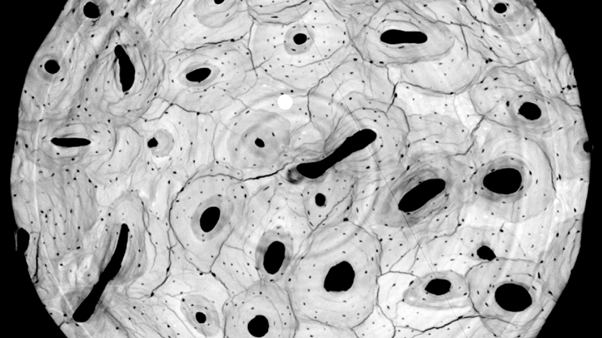

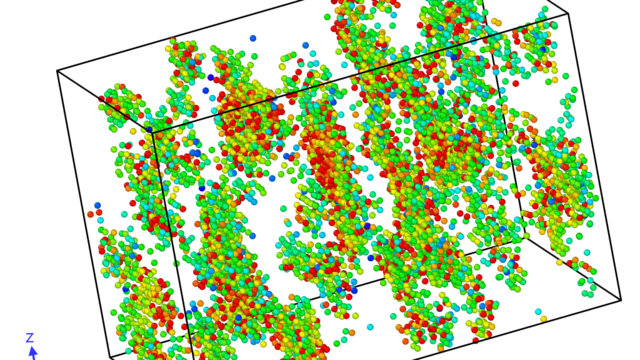

We have established a new focus on digitalisation in materials science and engineering. This includes investigating the behaviour of biological tissues and organs, with particular emphasis on mineral-reinforced biopolymers, bioceramics, bioglasses, and their composites. Mineralised material architectures lie at the heart of our research, as these materials are intrinsically circular, generate no non-recyclable waste, and often exhibit properties superior to those of conventional technical materials.

To explore material properties, we use a combination of advanced experiments, numerical methods, and mathematical models – spanning molecular to macroscopic length scales. Digital representations of material architectures, along with algorithms for data processing and interpretation, are essential tools in understanding the relationships between process, function, and structure – both in technical systems and in pathophysiological (biomedical) contexts. Our experiments employ established methods such as XRD, EDX, µCT, SEM, and XRF, as well as high-resolution analyses at large-scale research facilities like synchrotrons.

While we embrace new directions, we remain grounded in our scientific heritage.

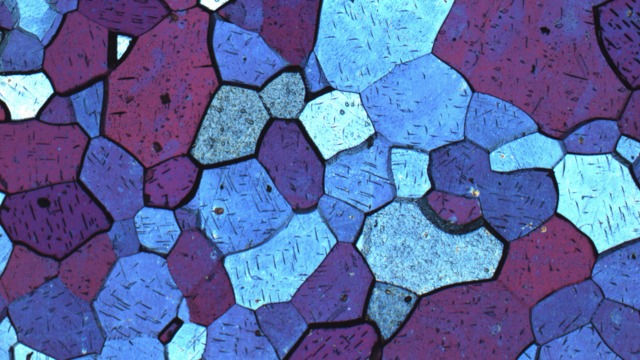

Our shift towards digital and bioinspired materials research strengthens and complements – rather than replaces – our traditional areas of expertise. In recognition of our legacy, we continue to study microstructure–property relationships in metallic materials, particularly in light metals such as aluminium, magnesium, and titanium, as well as in copper and iron-based alloys.

We focus on material strength under a range of loading conditions – including static (creep), quasi-static (tensile and compressive), cyclic (fatigue), and dynamic (impact testing). We also investigate damping behaviour in soft magnetic materials, long-term dimensional stability, and grain refinement in cast alloys. In addition, we work to optimise fatigue resistance through mechanical surface treatments such as shot peening and roller burnishing, and examine the electrochemical corrosion behaviour of metallic materials. We apply our full suite of analytical techniques – including scanning and transmission electron microscopy – to practical failure analyses. Based on the insights gained, we develop tailored recommendations for specific real-world applications.

Through interdisciplinary research, hands-on education, and close collaboration with industry and society, we empower a new generation of scientists and engineers to help shape the transition to a regenerative high-tech society.

Together, we develop materials – and mindsets – for a better world.

About us

Contact

Secretary's office

A. Brinker

Phone: +49 5323 72-2770

E-mail: iww@tu-clausthal.de

History of the institute

Our team

You can find more information about our team members here